Delaying replacement may seem reasonable when a system still runs, especially if comfort is acceptable most days. Problems often build quietly, then show up as breakdowns, comfort swings, or rising disruption during peak weather.

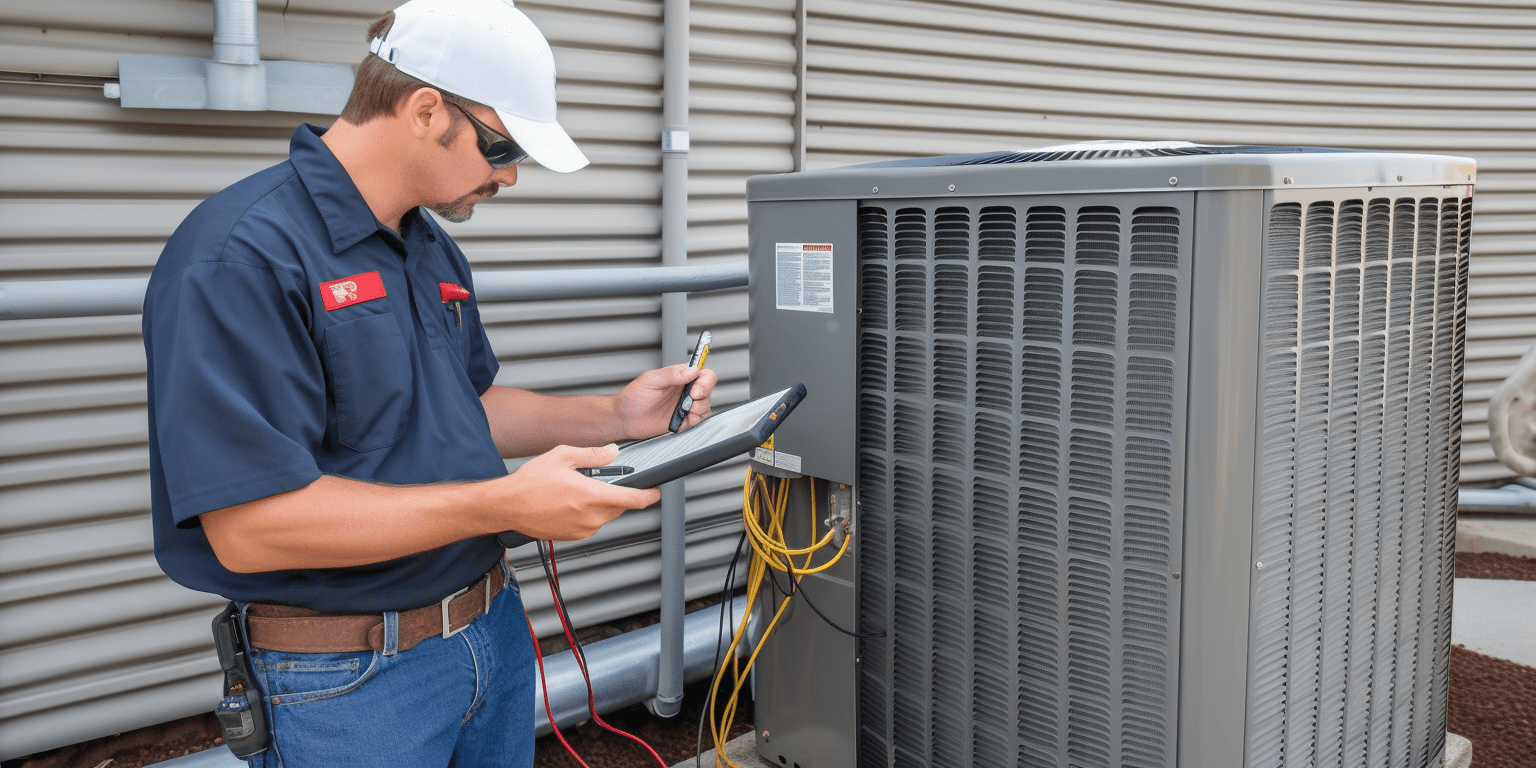

Professional planning that includes HVAC installation helps homeowners understand how replacement timing affects safety, reliability, and household schedules. Postponing replacement can increase strain on major parts, raise the chance of sudden failure, and make indoor comfort harder to manage during seasonal extremes. Clear information helps homeowners weigh risk and choose the most practical next step.

When Postponing Replacement Starts Raising Household Risk

Replacement delay becomes a bigger concern when reliability is already unstable or when comfort problems are growing. A system that struggles under load can develop repeated failures, unexpected shutdowns, and airflow issues that affect daily routines. A professional evaluation helps confirm whether the system can reasonably continue without frequent interruptions.

Common risk signals include:

- Breakdowns that occur closer together over time

- Comfort swings that grow more noticeable during peak weather

- Longer run times that leave rooms unevenly conditioned

- Frequent cycling that increases wear on controls and motors

- Humidity control problems that affect indoor comfort

- Odors or noises that keep returning after service

Many homeowners delay replacement because repair feels faster in the moment. A technician can explain when continued HVAC repair is likely to restore stability versus when repairs may only keep an aging system operating temporarily.

For guidance on problem patterns that often point toward replacement, visit our blog, “Which HVAC Problems Mean Replacement Is the Better Option?”

Comfort, Air Quality, and Reliability Effects That Often Grow Over Time

Performance decline usually affects comfort first, then reliability. Rooms can become harder to keep even, and indoor humidity can shift in ways that affect sleep and daily life. Airflow restrictions and system wear can also make indoor conditions feel inconsistent, especially during extended high-demand periods.

Homeowners often notice:

- Hot and cold rooms that change during the day

- Slow recovery after thermostat adjustments

- Airflow that feels weaker than past seasons

- Damp or stale indoor feel during the cooling season

- More frequent system lockouts or resets

When a system cannot keep up, planning for HVAC replacement often becomes more practical than repeated interruptions. Some households also begin searching for HVAC replacement near me during peak weather when comfort issues become difficult to manage.

For a broader timing framework, check our article, “How Do You Know It’s Time for HVAC Replacement?”

HVAC Problems That Become More Expensive in Disruption, Not Money

HVAC replacement delays often cause operational disruptions, not just higher repair costs. As systems age, failures are more likely during peak heat or cold, comfort becomes inconsistent, and scheduling timely service becomes more difficult. Even without considering HVAC replacement costs, homeowners experience real impacts: downtime, routine interruptions, and reduced indoor comfort.

Common HVAC Problems that become more disruptive with delay include:

- Repeating control faults that cause random shutdowns

- Compressor or motor symptoms that worsen under heat load

- Refrigerant and coil concerns that keep returning

- Airflow problems that create longer run times

- Moisture management issues that affect comfort consistency

A professional can evaluate whether continuing service is likely to remain stable or whether reliability risk is rising too quickly. For many homeowners, discussions about HVAC replacement costs are part of the planning process, yet decisions still depend on system condition, home needs, and reliability expectations.

For a closer look at aging-system performance, visit our blog, “Can an Aging HVAC System Still Be Trusted to Perform Well?”

How Pros Evaluate Risk When Replacement Gets Delayed

Professionals evaluate risk by focusing on reliability under load, safety, and the likelihood of repeated failures. Testing and inspection provide clarity on whether the system can handle seasonal demand without frequent interruptions.

Load handling and performance testing

Technicians evaluate whether the system can maintain comfort during peak weather, including temperature split, airflow delivery, and cycling behavior.

Electrical and control stability

Control faults and electrical wear can create unpredictable shutdowns. A professional inspects connections, protective devices, and control response.

Component wear and serviceability

The availability of major components and parts influences how practical continued service remains. Technicians assess how often failures recur and whether support is becoming more difficult.

Planning an appropriate replacement scope

Replacement planning can be different for homes and businesses. Some property owners explore residential HVAC replacement for comfort and scheduling needs, while others consider commercial HVAC replacement when uptime matters.

A professional evaluation provides a clear view of risk and supports timing choices based on real system behavior.

Why Delay Can Increase Strain on Your HVAC System

System strain often increases when equipment runs longer, cycles more frequently, or operates closer to its limits during peak demand. That stress can accelerate wear on motors, controls, and refrigerant-related components. Delay can also reduce flexibility, since replacement may become urgent during a heat wave or cold snap.

Signs of rising strain include:

- Longer cycles that still leave rooms uneven

- Increased cycling during mild weather

- More frequent service calls for different issues

- Noises that indicate mechanical wear under load

Many homeowners rely on ongoing HVAC services to keep an older system operating safely. Professionals can assess whether the system is stabilizing or whether strain indicators indicate that replacement timing should be moved sooner.

Risk Factors That Often Increase With Replacement Delay

Delaying HVAC replacement can increase operational and planning risks over time, especially as system components approach their limits. Comparing homeowners’ experiences with professional evaluation criteria clarifies how these risks tend to develop over time. The table below highlights common risk areas, what homeowners often notice, and why technicians pay close attention during inspections.

The next step often involves deciding whether repairs can realistically restore stable operation or whether proactive replacement planning provides a safer, more predictable path forward.

Choosing a Practical Path Forward Without Pressure

Replacement timing decisions are easier when homeowners focus on reliability, comfort, and household scheduling needs. A professional evaluation helps determine whether repairs can restore reliable operation or whether replacement is a better way to reduce risk.

Helpful decision factors include:

- Breakdown frequency is increasing

- Comfort swings are growing more noticeable

- Peak-season performance is declining

- Electrical or control issues are recurring

- Scheduling flexibility is shrinking

A technician can recommend a service path that fits the system condition and home needs, without relying on assumptions.

Plan Replacement Timing With Clear Risk Awareness

Delaying replacement can increase the risk of peak-season breakdowns, comfort issues, and recurring disruptions. A professional evaluation clarifies whether the system can reasonably continue or whether replacement planning is the safer way to protect comfort and schedules. Precise timing also supports better planning and reduces the chance of urgent decisions.

AC Repair DFW in Bedford, TX, works with homeowners to evaluate system condition, operating reliability, and performance trends to determine whether continued operation is reasonable or if replacement planning is the safer path. Our approach focuses on clear guidance that supports informed decisions before problems become urgent.

Contact us today or call us to schedule a professional HVAC evaluation focused on risk awareness and replacement timing. Our team can review system performance, explain realistic options, and help plan the next step with confidence.

Frequently Asked Questions

What factors affect the performance of an HVAC system?

HVAC performance is influenced by system age, maintenance history, airflow, insulation quality, and thermostat accuracy. Environmental conditions, duct condition, and proper system sizing also play a significant role.

What is the most common cause of HVAC system breakdowns?

Lack of regular maintenance is the most common cause of HVAC breakdowns. Dirty filters, neglected components, and unchecked wear often lead to system strain and eventual failure.

What is the most critical safety concern in an HVAC shop environment?

Electrical hazards and pressurized refrigerant systems present the most critical safety concerns. Proper training, protective equipment, and safety protocols are essential to prevent injury. For up-to-date refrigerant handling and HVAC safety guidance, consult the Environmental Protection Agency.

What happens if an AC is not used for a long time?

When an AC sits unused, components such as seals, motors, and electrical connections can degrade. Dust buildup and moisture may also affect performance when the system is restarted.

Why does an air conditioner need to sit for 24 hours after installation or moving?

After moving or installing an air conditioner, oil inside the compressor needs time to settle back into place. Allowing the unit to sit helps prevent internal damage when the system is powered on.

How often should an AC be replaced?

Most air conditioners are replaced every 15 to 20 years. Replacement timing depends on system efficiency, repair frequency, and overall performance rather than age alone.

Is it worth repairing a 10-year-old air conditioner?

Yes, repairing a 10-year-old air conditioner is often worthwhile if the issue is minor and the system has been well-maintained. Major repairs may require a cost comparison with replacement options.

How do I know if my air conditioner needs to be replaced?

Replacement may be needed when cooling becomes inconsistent, energy bills rise, or repairs become frequent. System age and declining efficiency are also strong indicators. For trusted efficiency guidance and best practices for high-performing HVAC systems, visit ENERGY STAR.

How long is too long for an AC unit to run?

An AC unit running continuously without reaching the set temperature may indicate inefficiency or system problems. Extended run times often point to airflow issues, refrigerant problems, or poor insulation.

How long can an air conditioner sit without being used?

An air conditioner can sit unused for several months without immediate damage. Long periods of inactivity may still require inspection before restarting to ensure components operate correctly.